With the vertiginous expansion of electric vehicles (VE)the fate of their exhausted batteries is no longer only an environmental challenge, but also a global strategic opportunity. Traditionally, the lithium It is extracted from salares or open -pit mines, methods that carry a strong ecological impact and depend geographically on the call “Lithium triangle” -Forming by Argentina, Bolivia and Chile.

Today, not only does it matter where Lithium is obtained, but as It is reused. In that frame, the teacher’s team Kyoung-Shin Choifrom the University of Wisconsin -Madison, developed an innovative electrochemical technology to recover lithium of used batteries LFP (Lithium-Hierro-Phosphate). The team also integrates it Do-Hwan Nam and Brian M. Foster.

Why are LFP batteries relevant?

Although they have lower energy density than other chemicals based on nickel, manganese or cobalt, LFP batteries stand out for their greater thermal stability, lower cost and lower toxicitywhich makes them preferred by manufacturers such as Tesla and Byd.

The main challenge is that, when these batteries are discarded, lithium is almost the only component with significant economic value. Materials such as iron and phosphate have little recyclable value, making it difficult for conventional recycling to be profitable.

electric car batteries

Choi’s solution: efficient and scalable

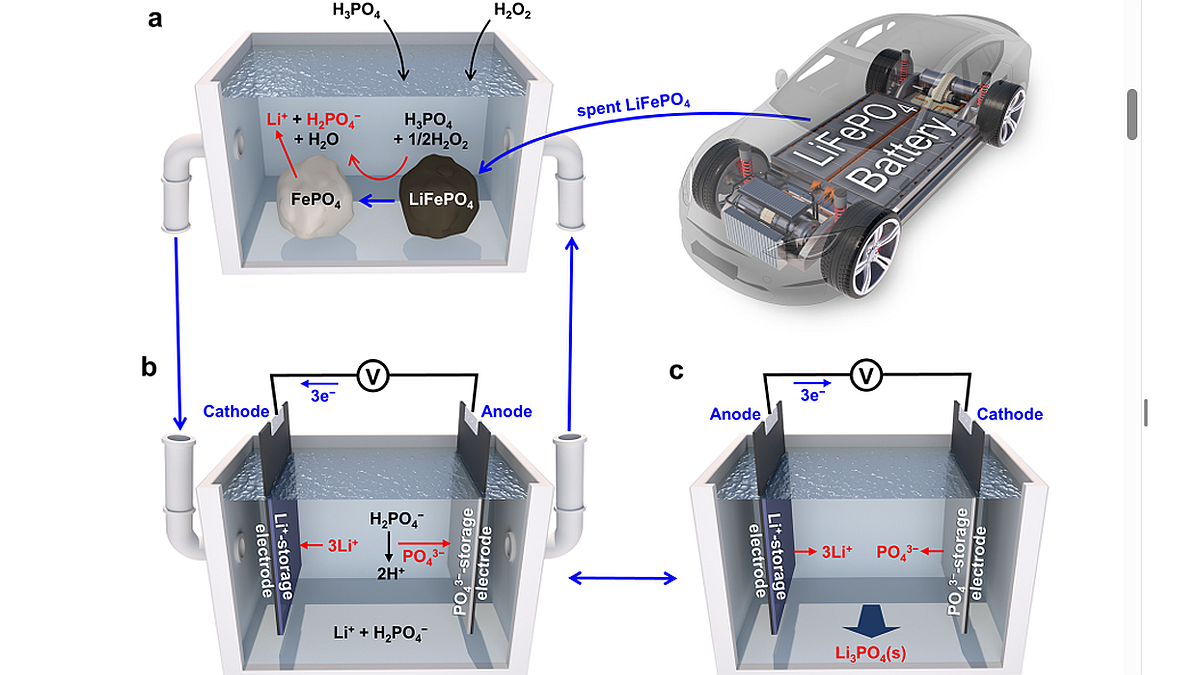

The process designed by the Choi team does a recovery selective lithium ions in two stageswithout requiring extreme temperatures or large amounts of chemical reagents. This makes it a clean, efficient and practical alternative to massify recycling.

They have already demonstrated their effectiveness with commercial batteries and with what is known as “Black Mass“-The crushed mixture that results in recycling plants.

In addition, a prototype is underway, and a Technological Startup to bring this solution to the market competitively. Global manufacturers have already shown their interest, seeing in this technology a key tool to reinforce the resilience of their supply chains against geopolitical crises and bottlenecks in mining.

Choi’s innovation comes at a key moment. From 2031the European Union will require that a minimum percentage of lithium in new batteries come from Fuentes Recycledforcing manufacturers to incorporate circular economy solutions with normative support.

Energy 4.JFIF

Batteries After 2 years of studies, they estimate that they could reach the market within 10 years.

What happens to the price of lithium

In the last 10 daysLithium showed clearly bullish movements. He Price of lithium It now reaches some 11,169 dollars per tonalthough a 0.43% on August 29 Regarding the previous day. In the last month the advance was from 9.18%while compared to the previous year, it records a rise of 6.20%.

This rebound coincides with Temporary closures in Chinese plants And an explosion in a Chilean operation, events that reduced the global offer and raised quotes.

In parallel, companies such as Albamarle They saw their shares upload a 25% in Augustwhen rebalancing supply and demand, although analysts remain cautious about the sustainability of this trend.

What are the characteristics of the new electrochemical process to recycle lithium

- Cheaper and more clean than current methods.

- LFP (Lithium-Hierro-Phosphate) batteries approach.

- Growing automotive and regulators support.

- Prototype in progress, startup in formation.

- Key to comply with European regulations since 2031.

Paper Complete and Original in ACS PubliS

Reetutilizable Lithium Batteries ACS Publications

Source: Ambito

I’m a recent graduate of the University of Missouri with a degree in journalism. I started working as a news reporter for 24 Hours World about two years ago, and I’ve been writing articles ever since. My main focus is automotive news, but I’ve also written about politics, lifestyle, and entertainment.