A new type of robot automatically dismantles the battery packs that are installed in e-cars. He is ten times faster than a human. The recycling of batteries is a basic requirement in order to be able to convert traffic to e-cars.

How sustainable e-vehicles really are depends mainly on two factors. On the one hand, there is the current that flows into the batteries. It has to be green for the e-car to be climate-neutral. The other factor concerns the batteries. They have to be completely recycled, under no circumstances should there be mountains of toxic electronic waste.

Recycling costs

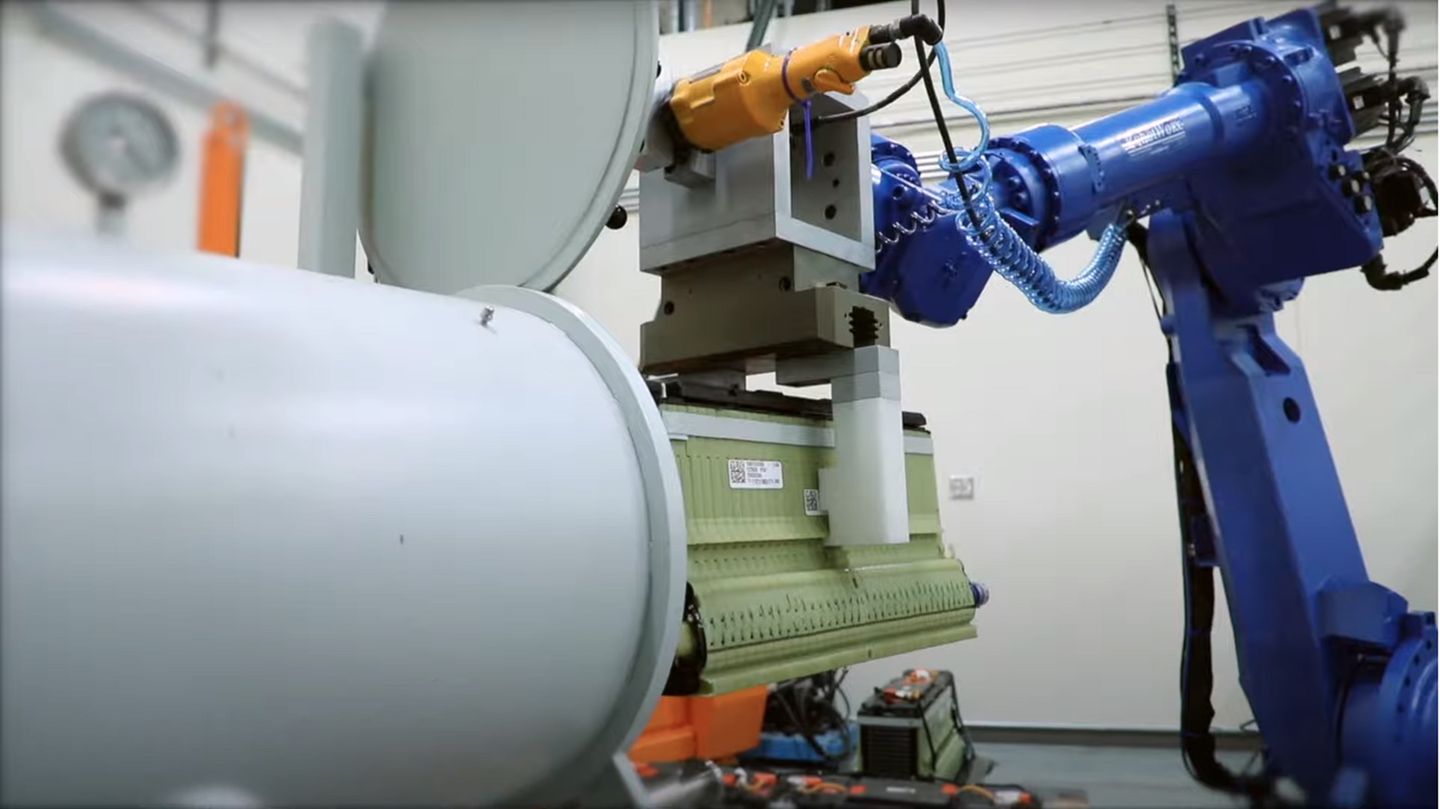

However, the dismantling of the batteries is very complex, which is also due to the fact that today’s battery systems are extensively protected from damage. Scientists at Oak Ridge National Laboratory (ORNL) have developed a robot that automatically dismantles old electric vehicle batteries. There will be no way around robots in this task. Because of the toxic chemicals and the dangers of the electricity, it would be difficult to use humans. In addition, dismantling the packs is laborious and would be correspondingly expensive if working hours were paid.

Only a small percentage of lithium-ion vehicle batteries are recycled today, and the majority of the processes used to do so are not automated, said Tim McIntyre, senior researcher in ORNL’s electrification and energy infrastructure division. The system is based on an existing robot that removes rare earth magnets from old hard drives. The new system is not restricted to a specific type of battery pack. “The human touches the battery pack for the last time when it is placed on the production line. Then the robot picks up the pack and breaks it down into all its individual parts,” says team leader Tim McIntyre.

Fully automated process

The fully automated robot dismantles the pack down to the individual cells. They can then be dismantled further to remove the materials. The cells can also be upgraded again and built into new power storage systems. The system should work ten times as fast as humans. This is because, for safety reasons, skilled workers have to go through a lengthy process to first fully discharge the batteries before they can be manually disassembled. The robots, on the other hand, dismantle the pack even if there is a residual charge.

+++ Read also: The danger of batteries in household waste – “It’s a miracle that nobody has ever died” +++

Long forward

Team member Tom Lograsso also emphasizes that it is important to plan for dismantling and reuse when designing the drive train in the future. This is the only way to recycle that is also economical.

Compared to other tasks that arise from the challenges of climate change, recycling batteries has a great advantage. There is a lot of time to find optimal solutions. Currently, only a small number of car batteries are being recycled. The number of registrations for e-cars is now increasing, but the batteries will last an average of ten years or more. It takes a correspondingly long time for the wave of new registrations to lead to a noticeable increase in recycling.

Those:

I am a 24-year-old writer and journalist who has been working in the news industry for the past two years. I write primarily about market news, so if you’re looking for insights into what’s going on in the stock market or economic indicators, you’ve come to the right place. I also dabble in writing articles on lifestyle trends and pop culture news.