podcast

Heinz-Glas has been producing flacons for perfumes for 400 years. But the high energy prices are threatening the glass industry in Upper Franconia. Without natural gas, the plants would cool down and be destroyed – so prepare for the worst.

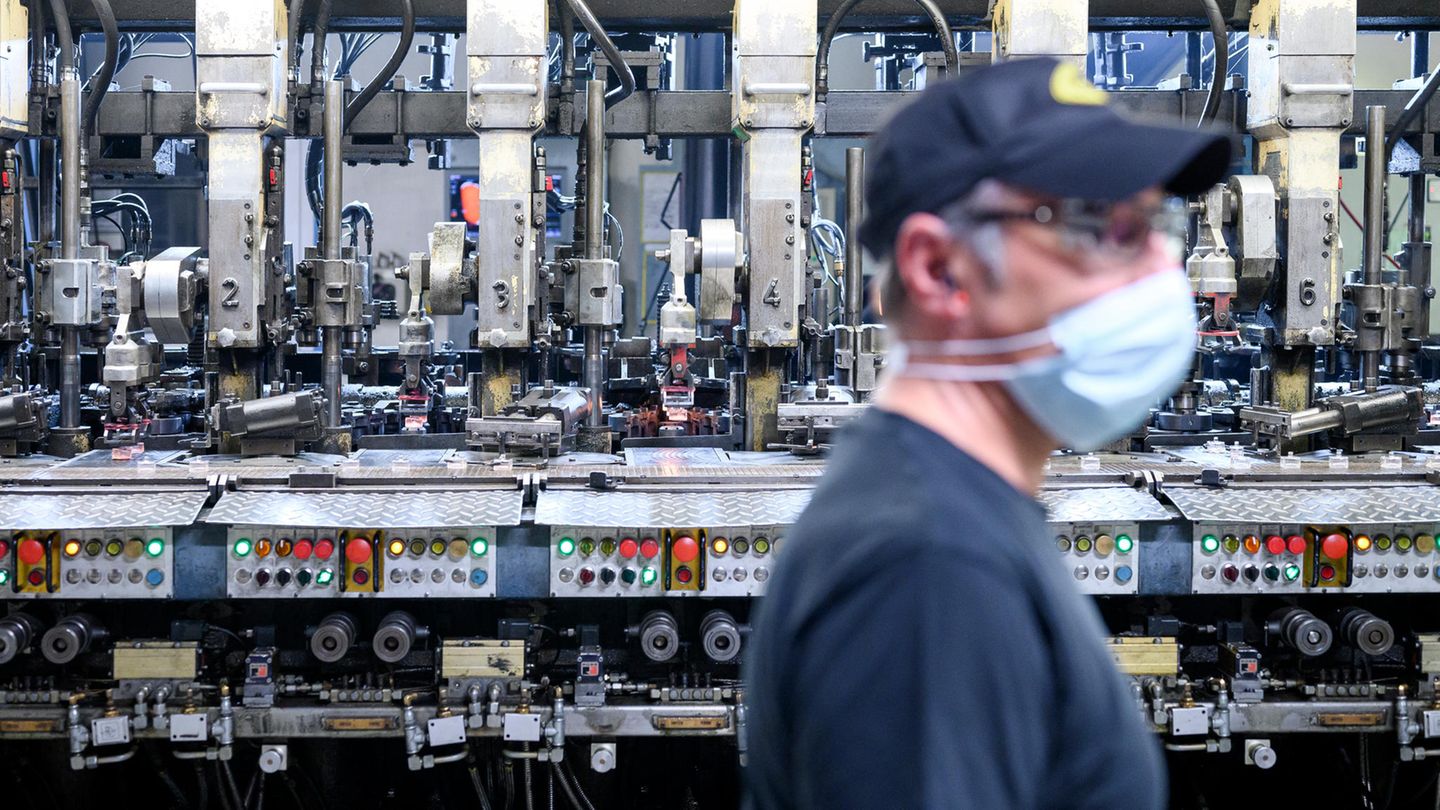

Full order books, a growing market, 300 different bottles every year in quantities between 20,000 and 15 million, a turnover of 330 million euros: At first glance, the situation of the bottle manufacturer Heinz-Glas, a family company with 400 years of history, is very good Good. And yet there is a big problem. “With the energy prices that we currently have, we no longer work economically,” said Christian Fröba, who manages the operative business. “We’re sometimes talking about a factor of 20 compared to the beginning of last year. The market no longer works.” In other words: Heinz-Glas burns money every day.

The company is based in Kleintettau, a village with 800 inhabitants in Upper Franconia, 1500 people work here. Other well-known manufacturers are based in the Rennsteig region, including Gerresheimer, Röser and Wiegand-Glas. The latter has 2,000 employees and produces a quarter of all glass beverage bottles that are required in Germany. Every fourth bottle worldwide comes from Heinz-Glas, the company has 16 locations worldwide, including China, Poland, India and Peru.

The successful cluster is under threat because, on the one hand, glass production requires a lot of energy at temperatures of 1500 to 1600 degrees. “The glass industry on the Rennsteig requires as much electricity as a town with 400,000 inhabitants and as much natural gas as 85,000 single-family houses,” calculated Fröba.

The glass manufacturers recently called for help with a video that was viewed 60,000 times within 48 hours – hashtag #Alertstuferot. “The glass industry in Germany has a very small lobby or no lobby,” said Fröba. “It was important for us to make ourselves heard.” Carletta Heinz, who runs the family business in the 13th generation, outlined the situation in drastic words: “If things continue like this, we might be able to stay afloat for another six months,” she told the “Süddeutsche Zeitung” at the end of February. “After that it’s over.” The high energy costs make glass production in Germany uneconomical. And “then it just takes place in other countries, with fewer regulations and under worse conditions.”

There is a risk of a “total loss”

Another problem is that production has to run around the clock. With a gas embargo, you cannot shut down production. “The melting tanks contain the hot molten glass and have to be heated continuously,” says Heinz-Glas COO Christian Fröba. “We operate our systems 24 hours a day, seven days a week. If the energy supply is interrupted, the glass in the melting tank cools down and freezes.” The result is a “huge chunk of glass”, depending on the size of the plant from 50 to 600 tons. “It’s a total loss. Such a tub costs between 15 and 50 million euros.” The construction time of a plant is one year. According to Fröba, there are 15 such melting tanks in the Rennsteig region.

The glass industry must reduce its dependence on natural gas. She is already working on that, some works run electrically. “The glass industry is actually predestined for decarbonization,” said Fröba. Heinz-Glas is now preparing for various scenarios in the event of a gas embargo. The plants would then be kept warm, but no longer produce. “The dependence of the people here in the region on the glass industry is very high,” says Fröba, who grew up in Upper Franconia. In the worst case, you would have “8000 employees who would be without wages and bread”.

Also, listen

- Why bottles are becoming more and more complex to produce

- Why Heinz-Glas had to put some investments on hold

- What people in Kleintettau and other places think

All episodes can be found directly at , or or via .

Source: Stern

Jane Stock is a technology author, who has written for 24 Hours World. She writes about the latest in technology news and trends, and is always on the lookout for new and innovative ways to improve his audience’s experience.