Seaborg Technologies wants to build thousands of mini-reactors. The systems are said to be very cheap and are designed in such a way that even bombs do not cause a nuclear disaster.

Germany is turning the juice off of nuclear power plants, but nuclear energy is experiencing a renaissance around the world. One of the main trends is the construction of smaller reactors of a new type, in which, due to the design, no worst-case scenario can occur. These systems are to be built in factories and only finally assembled on site. One of the best-known advocates is Bill Gates, who has his own type of reactor developed and built.

With the miniaturization of power plants, another idea is becoming more popular: if the power plants are getting smaller, why not mount them on a floating platform? In this way, they could be completely built in a shipyard assembly hall and easily brought to their destination. So far, only Russia has produced floating nuclear power plants, but a start-up from Copenhagen is now announcing plans to do so. Unlike Rosatom, however, the Danes are only just beginning. “Seaborg Technologies” goes a step further than Rosatom or Rolls Royce (Rolls Royce wants to build mini reactors). The reactors of both companies are based on nuclear facilities that the military already uses for ships and submarines.

The “compact Molten Salt Reactors” from Copenhagen, on the other hand, should only be the size of a shipping container and literally be mass-produced. And mass means: by the thousands. As the name suggests, the fuels are mixed with fluoride salts. This mix liquefies at temperatures above 500 degrees. The fissile material is not cooled with water or sodium, but with the salt. Among other things, this has the advantage that if the coolant is damaged, it does not escape explosively as hot water vapor, but rather solidifies on contact with the air. Like other coolants, the salt is radioactively contaminated, but it cannot enter the atmosphere as a cloud. Like a volcanic eruption, “lumps of lava” remain in place.

There is a salt plug at the bottom of the reactor. Should the temperature in the reactor core rise in an uncontrolled manner for any reason, this salt will melt and the contents of the reactor core will drain into cooled tanks. The separation stops the nuclear reaction and the liquid content solidifies.

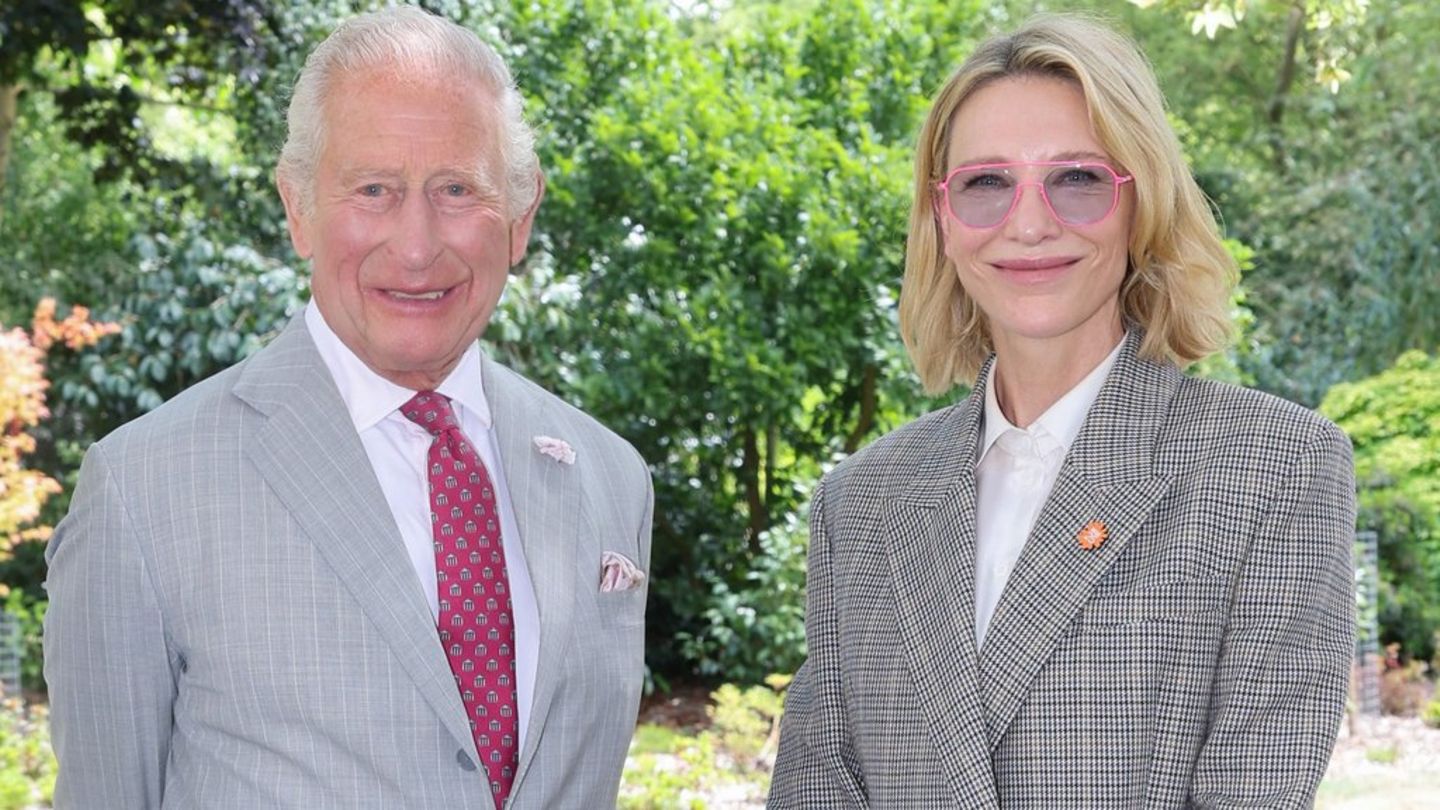

These simple measures, says Troels Schönefeldt, co-founder and CEO of Seaborg Technologies, radically re-pose the question of nuclear safety, moving away from total accident prevention to a much simpler impact mitigation. The security philosophy sounds daring. In a conventional power plant, accidents should definitely be avoided, which drives up the costs of the systems enormously. The “compact molten salt reactors”, on the other hand, are designed in such a way that accidents are easy to control and therefore they do not have to be avoided at all costs. Troels Schönefeldt, CEO and co-founder of Seaborg. “We’re taking a different approach. We don’t reduce the probability of an accident to zero, there will be accidents. We want to avoid them as much as possible, but there will be accidents.”

“Instead of reducing the likelihood of an accident, we are reducing the consequences of the worst disaster.” Even if the reactor were deliberately bombed, the fluoride salt would just flow out of the reactor, solidify, and lie around in chunks. “Then you shouldn’t go into this field. You should keep a distance of three or seven meters. But then you can go there with a Geiger counter and clean up the chunks. That changes the basic security profile of the technology. And with that we change the costs, what in turn changed the business model. ”

David William is a talented author who has made a name for himself in the world of writing. He is a professional author who writes on a wide range of topics, from general interest to opinion news. David is currently working as a writer at 24 hours worlds where he brings his unique perspective and in-depth research to his articles, making them both informative and engaging.