Manufaktur visit

The little black man: This is how Chanel mixes up the world of luxury watches

Copy the current link

Add to the memorial list

Chanel also sets standards in terms of luxury at clocks. When you visit the company’s own manufactory, you meet craftsmen with fine fingers – and a penchant for merciless.

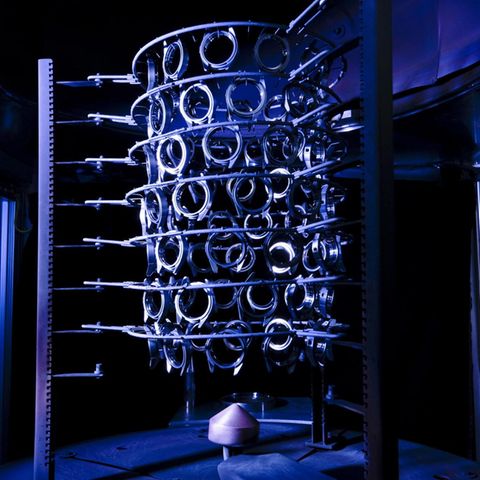

The precious piece rests on a glass base. It is hardly larger than a two-euro piece, and yet 172 parts are installed in it: screws, gears, even rubies. Everything has to interlock in a confined space. The man who succeeds the big one on a small scale lifts a screw with tweezers and carefully puts it in the matt black housing. In order not to leave any prints, he wears pink fingerlings, plus a white coat with lion’s head emblem. It is the recognition mark of the watchmaker who build highly complex works in the Chanel manufacture.

Wait, Chanel and watches? In fact, the Paris fashion brand also mixes in the Haute Horlogerie, the high timepiece, and has secured a top position between industry sizes such as Bulgari, Piaget and Patek Philippe. Company founder Gabrielle “Coco” Chanel presented his own jewelry collection as early as 1932, but the clocks only followed in 1987. Unlike many fashion brands, which at the time troubled their good name for every kind of license, Chanel has been relating to high -quality watches since then.

Chanel makes blue

In the in-house manufacture in La Chaux-de-Fonds in Switzerland, the artisans are able to build complications such as a chronograph or a flying tourbillon. Since 2016 they have been producing five new clockworks alone. This is roughly as if Porsche presented a new car type every two years.

The fact that visitors are allowed to look at the watchmaker’s fingers rarely. But this year there is an anniversary at Chanel: the model “J12” Is 25. A clock that once brought new swing to the slowly ticking watch world. On the one hand because it was made of a material that only used rado next to Chanel: ceramic. Seven times harder than stainless steel, almost frosted and with permanent shine – it was quickly taken up by other brands and is now considered an industry standard.

In addition, it was “J12″which initially existed in black and later in white, one of the first Unisex watches. Although it was manufactured by a label for women’s fashion, men were also interested in the cool, technically demanding design. The then creative director Jacques Helleu had been inspired by sleek Iacc yachts of the America’s Cup. The racing boat “J12” became the namesake.

Women also accepted the model thankfully, because they were long ignored by manufacturers of mechanical watches as a target group. It was assumed that they were also satisfied with quartz works on the wrist, prettied up with colored dials and sparkling diamonds. Today unisex watches are common, but still not the rule.

For the anniversary edition of the “J12” Therefore, put Chanel on an innocent color again: a dark, matt blue. The studios in La Chaux-de-Fonds worked on implementation for five years. Then finally the tone of the ceramic and the sketches of the Paris design office, led by Arnaud Chasta, matched the finished works.

All models of the “Bleu”-Serie made by hand, but the Haute-Horlogerie pieces receive extra treatment. They are built exclusively by a watchmaker. The little black man, which the man put together in the white lion’s pet, belongs to the caliber 5 of a flying tourbillon. It was specially made for this model, which represents the crown jewel of the line. His housing decorate 34 sapphires, and a great diamond seems to float inside. However, it is attached to an open tourbillon cage, which should ensure higher accuracy. A complication that can cost a few hundred thousand euros.

Whichever new model leaves the manufacturer: each prototype must previously go through the in -house torture chamber. It is led by two friendly -looking gentlemen who turn out to be merciless. They stretch tapes, hammer on ceramics and drop watches from a great height. 3000 tests must survive every model. Quality comes from agony.

Source: Stern

I am an author and journalist who has worked in the entertainment industry for over a decade. I currently work as a news editor at a major news website, and my focus is on covering the latest trends in entertainment. I also write occasional pieces for other outlets, and have authored two books about the entertainment industry.